PROCESS PROJECTS LTD (In Administration)

http://www.processprojects.com

We can assist in your enquiries for pressure vessels as built by Process Projects Limited.

Scope of supply

Manufacture

- • Pressure Vessels

- • Pipework

- • Filter Vessels

- • Tanks

- • Fabrications

- • Skid Modules

- • Fabrications

- • Machining

- • Instrumentation

Associated Manufacture

- • Machining

- • Instrumentation

- • Pressure & Leak Testing

Design

- • Vessel Code Calculations

- • AutoCad Drawings

Process Projects Ltd Pressure Vessels & Filter Vessels – Eastleigh UK

Telephone: 02380 647 888

Process Projects Ltd was based near Southampton in Southern England UK and occupied substantial facilities located near to the M3 and M27 motorways and a short distance from both Southampton Airport and Rail Terminal.

Process Projects Ltd specialised in the manufacture of products and equipment for the Process Industries.

Products Included:

Produced Water Module

Oil Industry (Offshore)

Code:

Vessels – ASME VIII DivI ‘U’ stamped

Pipework – ASME B31.3

Materials:

Carbon Steel – A516 Gr65&70 / A333 Gr6 / LF2

Nitrogen Module

Oil Industry Pressure Vessels (Offshore Norway)

Code:

Pipework – Norsok specs

Structure – Norsok specs

Materials:

Stainless Steel – A312 TP316L / A182 F316L

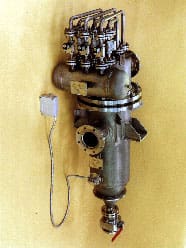

Filter Vessel

Oil Industry (Offshore)

Code:

ASME VIII DivI ‘U’ stamped

Materials:

Carbon Steel – A333 Gr6 / LF2

Flushing Vessel

Oil Industry

Code:

ASME VIII DivI

Materials:

Copper Nickel 90/10

Aerospace Industry pressure vessels:

Particle Separation Test Module

Aerospace Industry

Materials:

Vessel / Piping – Stainless Steel Grade 316L

Structure – Carbon Steel

Pharmaceutical Industry Pressure Vessels

Chill Module

Code: Pulse VesselPharmaceutical Industry Code: Powder Recovery Vessel

Code: |

Membrane Filter Housing

Pharmaceutical Industry

Code:

ASME B31.3

Materials:

254 SMO

Pulse Vessel

Pharmaceutical Industry

Code:

ASME VIII DivI ‘U’ stamped

Materials:

Vessel – Hastelloy C22 / C276

Reservoir – Stainless Steel 316

Tubesheet

Pharmaceutical Industry

Materials:

Hastelloy C22 / C276

Membrane Filter Housing

Pharmaceutical Industry

Code:

ASME B31.3

Materials:

254 SMO

Heat / Chill Module

Chemical Industry

Code:

Pipework ASME B31.3

Materials:

Carbon Steel – A333 Gr6 / LF2

Stainless Steel – A312 TP316L / A182 F316L

Membrane Filter Housing

www.processprojects.com

Chemical Industry

Code: ASME B31.3

Materials: 25Cr Super Duplex

Pulse Vessel

Chemical Industry

Code:

SME VIII DivI ‘U’ stamped

Materials:

Vessel – Inconel 601

Reservoir – Stainless Steel 316L

Filter Vessel

Nuclear Industry (UK)

Code: PD5500 Cat I

Materials: Carbon Steel – 224/490B

Process Projects Ltd

Unit 4c

Barton Park

Chickenhall Lane

Eastleigh

Southampton

Hampshire

UK

SO50 6RR

| Telephone: | 02380 647 888 |

| Fax: | 02380 647 880 |

| Email: | |

Registered in England No. 2419633

VAT Reg No. 568 5268 94